- Industry: Lettuce Grower

- Region: Europe

FromBoer turns crop feedback into actionable strategy with Gardin Pulse

- +5%

yield - €4,000

per hectare energy savings - Improved

climate control - Faster

decisions

Summary

- 5% higher yields by using live feedback to fine-tune lettuce production.

- €4,000 / ha energy savings by optimising their lighting.

- Improved climate control and faster decisions.

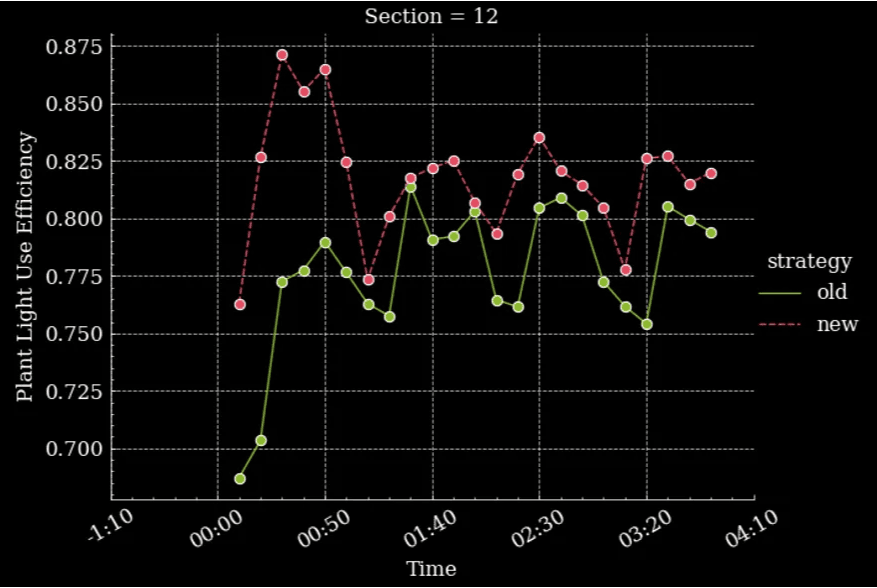

Fig. 1 Plant light use efficiency over time in section 12 of Fromboer greenhouse, showing an improvement using Gardin's new strategy (red).

"The sensor data contributes to a homogeneous production of high quality and to cost control. On balance, I estimate that the result per square meter is at least 5% higher."

Leonard Boer, Owner and Grower at FromBoer

Introduction

FromBoer, a family-owned greenhouse business in the Netherlands, has long been recognised as a beacon of innovation in horticulture. Founded in 1968 and now run by brothers Arjan and Leonard Boer, the company's 4-hectare semi-closed facility in Dinteloord is considered a benchmark for high-tech, sustainable lettuce production in Europe. Growing seven varieties of lettuce from seed for leading supermarkets, FromBoer faces the constant challenge of tailoring climate strategies to the unique needs of each variety—all while maintaining efficiency and profitability.

In 2023, the Boer brothers began a transformative collaboration with Gardin, adopting real-time plant photosynthesis sensors to bring the concept of plant-driven growing to life. The partnership has since delivered breakthrough improvements in how the greenhouse is managed, empowering Leonard to understand his crops not just by environment, but by how the plants themselves are responding.

Case 1: EC Optimisation Across Multiple Lettuce & Basil Varieties

FromBoer cultivates a diverse mix of lettuce and basil types, each with its own ideal conditions for light, nutrients, and climate. This diversity makes uniform decision-making incredibly difficult — what benefits one variety may harm another. One particularly complex challenge has been managing Electrical Conductivity (EC) in the irrigation water, which directly affects nutrient uptake and plant stress.

Traditionally, EC management relied on indirect indicators and periodic crop inspections. However, by using Gardin's photosynthesis sensors, Leonard could monitor the actual physiological response of each variety to different EC levels. With this insight, the team fine-tuned EC set points per variety and growth phase, improving nutrient efficiency without compromising quality.

This level of optimisation across ten varieties would have been impossible using conventional tools and visual assessment. Gardin's plant feedback data allowed FromBoer to reduce stress, increase homogeneity, and boost productivity in parallel through simple optimisation of photosynthesis.

"The dashboard doesn't tell us the exact cause of stress — but it shows clearly when something's wrong. That's enough to investigate and fix the issue before it affects the harvest... we're still learning — but every month, we grow better."

Leonard Boer, Owner and Grower at Fromboer

Fig. 2 - Health values in 9 different gutters and 4 different zones of Fromboer greenhouse, showing the impact of varying Electro Conductivity of irrigation solution on plant health. Health can be used as a tool for rapid feedback on optimal irrigation strategy.

Fig. 3 - Distribution plots to show the impact of EC on different gutters containing unique varieties of lettuce. Plant health of each variety is impacted differently by the changes in EC which must be chosen based on a compromise for all varieties.

Case 2: Energy Savings Through LED Optimisation

FromBoer's cutting-edge facility includes a mobile gutter system and water-cooled LED lighting — used extensively during the dark winter months at high cost. Using Gardin's chlorophyll fluorescence sensors in each growing department, Leonard was able to measure the photosynthetic response of his crops in real time as lights were activated. The data showed that a sudden increase in light was overwhelming the plants, reducing their photosynthetic efficiency and creating stress.

A simple change to the light start-up schedule — gradually ramping up light intensity to give the plants time to "wake up" provided a simple solution. The result was smoother adaptation, healthier crops, and a measurable reduction in energy usage, saving €4,000 per hectare per year without any loss in yield. Additionally, the reduced stress in the plant caused a higher light use efficiency throughout the entire rest of the day, delivering further benefits to plant productivity. In fact, Leonard estimates productivity increased by at least 5% per square metre as a result.

"Before, I mainly focused on the climate conditions in the greenhouse...with Gardin I can measure the effect of the climate conditions based on the plants themselves."

Leonard Boer, Owner and Grower at Fromboer

Fig. 4- Plant light use efficiency over time for two different sections of Fromboer greenhouse, showing an improvement using Gardin's new strategy (red) where LED lighting is dimmed at 50% for the first 60 mins of each day to allow up-regulation of photosynthesis.

Conclusion

Beyond individual interventions, Gardin's value lies in enabling continuous, data-driven optimisation. Weekly evaluation meetings between Gardin and FromBoer allow the team to interpret plant data, test hypotheses, and refine growing strategies. Ridder, the climate computer provider, has integrated Gardin's dashboard for seamless access — helping the Boer brothers align plant feedback with climate control in one view.

FromBoer's collaboration with Gardin exemplifies the future of horticulture: one where data from the plant itself drives every major cultivation decision. Whether fine-tuning EC across a complex crop mix or cutting thousands of euros in energy costs through optimised lighting, the results speak for themselves.

FromBoer is a leading lettuce grower in the Netherlands, well known for horticultural innovation. Their 4-hectare greenhouse in Dinteloord produces seven varieties of lettuce for leading supermarkets. Balancing the varied needs of these crops is a constant challenge, each responding differently to light, nutrients and climate. In 2023, FromBoer partnered with Gardin, adopting our real-time photosynthesis sensors to understand the plants themselves, not just the environment around them.

By tracking photosynthesis in real time, Gardin helped the team fine-tune nutrient and lighting strategies across a diverse crop mix. This reduced plant stress, improved crop uniformity, and increased yields, resulting in at least 5 percent higher production per square metre. Gardin also guided the optimisation of LED lighting schedules, which reduced energy use and saved €4,000 per hectare each year.

To start your journey towards understanding your plants better, please contact us to start the sales process.

RELATED CASE STUDY

15% Yield Increase with 25% Water Reduction

Should your case study be featured here?

Speak to our team to find out what Gardin Pulse will unlock for you.

Contact sales